Training

Lean Six Sigma -

Green Belt Certification

Green Belt Certification blends classroom learning with practical applications. The Lean Six Sigma Green Belt program is a program specifically designed to build Lean Six Sigmaexpertise and capability within an organization. This program creates lean champions internally. The course work is focused on applying Lean concepts and principles within a Value Stream Transformation model.

The Green Belt level of Certification is for organizations requiring individuals with the knowledge and expertise to conduct Lean Value Stream Transformations.

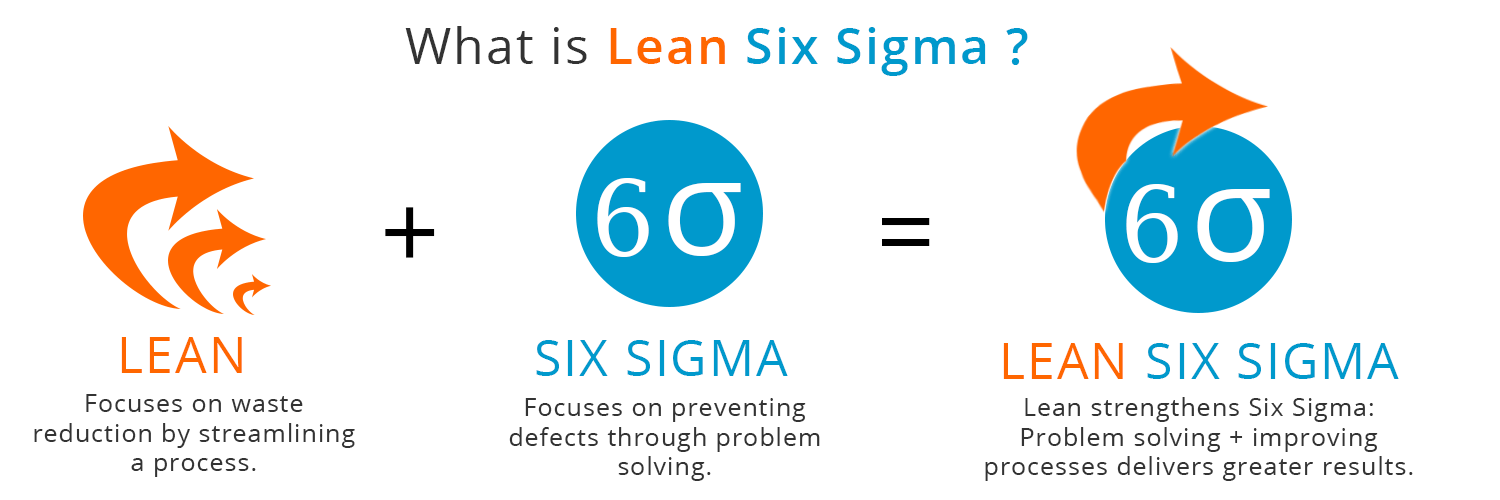

What is Lean Six Sigma?

In a constantly changing business environment, organizations must adapt at an ever-increasing pace. To survive, they must create efficiency and optimize their processes.

Lean and Six Sigma are two methods of process improvement that, together, make up Lean Six Sigma theory.

- Lean principles help create value for stakeholders through minimizing waste.

- Six Sigma principles help reduce defects by effectively solving problems.

- Together, Lean Six Sigma enhances problem solving and process improvement by making them faster and more efficient.

Why is Lean Six Sigma important?

Professionals with Lean Six Sigma credentials have long been valued in a variety of sectors. More and more industries are recognizing the value of implementing Lean Six Sigma for its ability to increase profits, decrease costs, and improve efficiency.

These are just some of the industries that leverage Lean Six Sigma principles: Health Care, Finance, Information Technology, Engineering, Operations, Project Management, Government, Not-for-profit, and more!

What will you learn?

- How to effectively plan, execute and lead using the Lean Six Sigma principles.

- Utilize the DMAIC (Define, Measure, Analyze, Improve, Control) method and other tools to successfully drive improved process solutions.

- Gain a deep understanding of quality and process improvement with an emphasis on leadership and collaborative work environment strategies.

Program Details

Participants in the Lean Six Sigma program will study in a blended-learning format, which includes both online and in-class components. During in-class sessions, students will participate in guided discussions, individual and group exercises, and practical applications. Students will also have the opportunity to participate in a field trip to a Lean Six Sigma organization. During online sessions, students will engage with readings, articles, exercises, self-evaluations, texts and videos.

Program Features:

- Blended format includes 5 modules (total of 10 days - 5 online, 5 in-class)

- Practical examples from different industries

- Open enrolment allows participants to network and learn from others in a variety of industries

- All materials and text are included in the cost of tuition

Topic Outline: Session 1 & 2

Objectives: Define, Measure & Introduction to Analytical Tools

After completing the first four days of training, participants will be able to gather any remaining information required for their project charter, and launch their process improvement projects.

- Explain Lean Six Sigma fundamentals (program and concepts) & DMAIC project methodology

- The eight sources of waste in lean organizations

- Establish & manage a project team

- Perform a CTQ Tree drill down to key processes

- Complete a SIPOC & process flow map

- Construct a Cause & Effect diagram

- Use forced ranking tools to prioritize information

- Prepare a Pareto analysis

- Establish key process metrics

- Prepare & execute a data collection plan

- Value stream mapping & value-added analysis

Objectives: Analyze, Improve & Control

This final four days of training will enable the participants to complete their analysis of the key processes being improved, as well as determining and confirming the process changes that will be initiated. The focus will also shift from “Improvement” to “Control” so that long-term sustainability of improvements can be achieved.

- Evaluate process variation & characterize defects

- Conduct a risk analysis (PFMEA, FTA)

- Correlation & regression analysis

- Conduct Surveys and Interviews for data gathering

- Kaizen, 5S, standardized work & cell design

- Visual management & visual controls

- Process rationalization

- Error-proofing & quick change-over

- Create and execute a process control plan

- Use of Process Control Charts

- Successful project closure

- Additional Topics Covered

- Managing Change

- Team Leadership –Managing the Team

- Project Team Selection

For further information or to speak with an Advisor Free Of Charge contact us: by email ... click here or call 888-980-7520

Thanking you in advance for the honour to be of service,

Constant Improvement Group

Workflow, Performance, & Innovation Leaders

Consulting, Support, Training

Home l About l Process l Performance l Innovation l Programs l Training l Resources l Contact